Documoto Blog

Stay updated on industry trends, tips, and insights with articles on interactive parts manuals, digital parts catalogs, and IPC for manufacturing.

The Hidden ROI of Documoto

Rethinking the Cost of Complexity Enterprise technical publications teams have long relied on powerful technologies like CCMS and DITA-based authoring. These platforms offer deep..

Unleashing the Power of Integration: How Documoto’s Headless API and Widgets Drive Real-World Results

Unleashing the Power of Integration: How Documoto’s Headless API and Widgets Drive Real-World Results In the world of equipment manufacturing and asset-heavy industries, there’s a..

Parts Catalogs: Understanding the Many Terms and Why They Matter

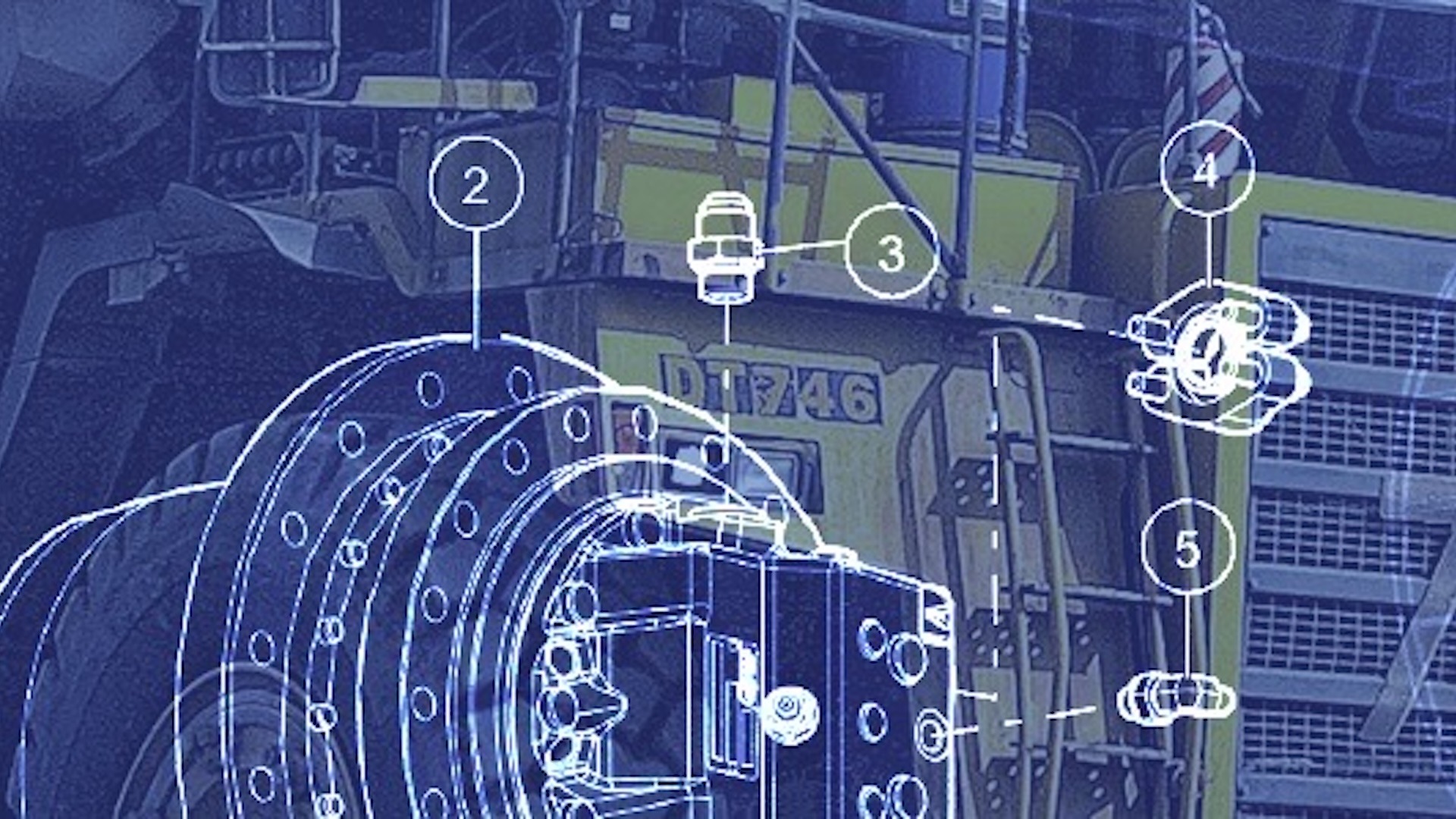

In the world of aftermarket parts and technical documentation, there’s no shortage of terms used to describe digital parts catalogs. Whether you’ve heard "Interactive Parts..

Don’t Wait for Perfection: Why OEMs Should Digitize Parts Content Now

For many OEMs, aftermarket parts sales are a growing revenue driver. Yet, too often, companies delay digitizing their parts catalogs because they feel their content, drawings, and..

Creating User-Friendly Technical Manuals: Best Practices for OEMs

Effective technical publications are essential for OEMs looking to streamline serviceability, enhance dealer and technician efficiency, and improve aftermarket support. Based on..

Valstone Corporation Expands Industrial Manufacturing Portfolio with Documoto

Montreal, December 13, 2024 – Valstone Corporation, a Montreal-based industrial technology company, is proud to announce the addition of Documoto to its portfolio of innovative..

Create and Edit Parts Pages in our NEW In-App Feature – Page Builder

Do you need help to keep print or PDF-based parts books up to date and delivered on time alongside your product delivery? Documoto’s authoring solutions allow manufacturers to..